Vertical farming, a modern method of cultivating a wide range of food products, presents a promising solution to some of today’s most pressing challenges—chief among them, ensuring food security, conserving resources, and combating climate change. With a growing global population, limited farmland, increasing resource scarcity, and environmental crises, vertical farming has the potential to fundamentally improve the way we produce food.

However, despite its numerous advantages, vertical farming faces significant economic hurdles. First and foremost, the high investment and operational costs pose a major challenge for potential investors and operators at the moment.

This article examines the current state of vertical farming in Europe, highlights its high potential as well as challenges, and discusses how companies can achieve a strategic balance between process control and cost-effectiveness to unlock the full potential of vertical farming.

Table of Contents

- Vertical Farming: Definition and Current Status in Europe

- Primary Economic Challenges of Vertical Farming

- Design-to-Cost: Ensuring Economic Viability from the Very Beginning

- Process Control in Vertical Farms: Balancing Necessity and Cost

- Additional Efficiency Factors: The Role of Location and Resources

- Conclusion: Strategic Compromises Between Control and Profitability

Vertical Farming: Definition and Current Status in Europe

What is Vertical Farming?

Vertical farming refers to an innovative agricultural method of food production conducted in controlled indoor environments. Plants are cultivated in vertically stacked layers, with environmental factors such as temperature, light, and CO₂ levels precisely managed to maximize yield and quality. These enclosed systems, often termed Controlled Environment Agriculture (CEA), are characterized by their ability to regulate all critical growth conditions.

A unique feature of vertical farming is its use of alternative growing mediums instead of conventional soil—for instance, nutrient solutions that enhance quality and productivity. Generally, we distinguish between aeroponic, aquaponic, or hydroponic systems. You can find out more about the different cultivation methods here.

This vertical indoor approach enables the cultivation of fresh foods irrespective of weather conditions or seasons, achieving optimal quality while using resources such as water and space more efficiently—thus, more sustainably—than traditional farming.

Vertical Farming as a Complement to Traditional Agriculture

The technology behind vertical farming offers substantial benefits, including solutions to pressing challenges such as dependency on weather and water scarcity, which increasingly plague traditional agriculture. While vertical farming is unlikely to replace conventional methods entirely, it serves as a complementary approach to sustainably ensure global food supply in the face of a growing population.

This is why, numerous companies are investing in vertical farming, with ongoing research dedicated to advancing this agricultural innovation. Although consumers are not yet able to choose vertical farm products in the supermarket of their choice, the industry is steadily progressing toward this goal.

The Current Status of Vertical Farming in Europe

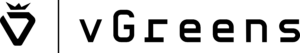

According to estimates by Market Data Forecast, Europe’s vertical farming market is expected to grow at an annual average rate of 22% over the next five years, reaching approximately $5.11 billion by 2029.

Germany, home to vertical farming startup vGreens, holds a particularly prominent position in Europe. Data Bridge Market Research forecasts that Germany, alongside countries such as the United Kingdom, France, and Belgium, will play a leading role in developing the European vertical farming market by 2030. This growth is driven by increasing demand for sustainable food and a need to reduce reliance on imports. Urban centers like Berlin, Paris, and Amsterdam offer ideal conditions for vertical farming projects, given their access to technology, funding, and environmentally conscious consumers.

Primary Economic Challenges of Vertical Farming

Despite its many benefits and Europe’s increasing interest, vertical farming poses economic challenges, particularly concerning costs. These can be broadly categorized into three main drivers:

- Investment costs

- Energy costs

- Labor costs

The actual cost of a vertical farm varies, however, depending on the location and size of the vertical farm.

Investment Costs

One of the initial challenges for those interested in building and operating a vertical farm lies in the capital expenditures (CapEx) required to establish a vertical farm. Depending on the size, the initial investment can amount to tens of millions of dollars, a figure feasible only for established market players.

Energy Costs

And even after a farm is constructed, operational expenditures (OpEx), particularly energy costs, remain significant. Fully enclosed CEA systems often require far more energy than traditional agriculture to achieve equivalent yields. Artificial lighting, temperature regulation, humidity control, and advanced automation systems necessary for optimal growth all contribute to high energy consumption.

Labor Costs

Vertical farming requires fewer seasonal workers for tasks such as harvesting and processing, thanks to automation and robotics. However, it demands highly skilled personnel for technological operations and maintenance. These specialized roles often command higher salaries than traditional agricultural labor, which presents a unique cost challenge in Europe, where wages are typically higher than in regions like Asia.

Design-to-Cost: Ensuring Economic Viability from the Very Beginning

A critical factor influencing the profitability of vertical farms is the overall cost structure. One promising approach to sustainable cost optimization is the “Design-to-Cost” methodology.

This principle emphasizes designing and developing vertical farms with a primary focus on economic efficiency to achieve profitability targets. Instead of aiming for maximum technical control or perfection, this approach prioritizes integrating only essential functionalities necessary for farm operation. By selecting technologies and systems that offer the highest value at the lowest cost without significantly compromising product quality, companies can reduce capital expenditures during the planning phase as well as save on operational costs throughout the farm’s lifecycle.

Process Control in Vertical Farms: Balancing Necessity and Cost

To ensure long-term viability in vertical farming, design-to-cost strategies need to be balanced with process control for optimal efficiency.

What is Process Control?

Process control refers to the precise monitoring and regulation of various environmental conditions in vertical farms, such as light, temperature, humidity, and CO₂ levels.

The Cost of Process Control

Comprehensive process control ensures optimized plant growth and consistently high-quality yields. However—as stressed before—this extensive control is expensive, requiring advanced systems that incur significant energy and maintenance costs.

If vertical farms are to be operated economically in the future, the question arises as to how much process control is really necessary. Reducing it to balance costs without compromising independence from external factors or product quality is a pivotal challenge in vertical farming. This compromise could be achieved through technological innovation that maintains efficiency while lowering expenses.

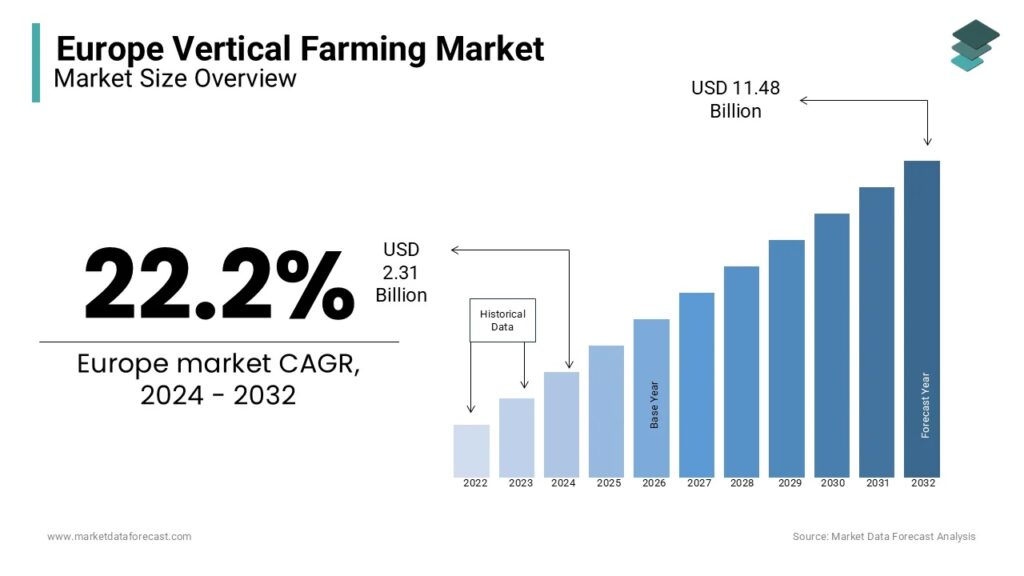

The Greenhouse Approach: A Hybrid Model

To address the issue of high costs, vGreens and its technical partners are exploring a hybrid solution combining fully enclosed vertical farming with greenhouse elements. This model utilizes natural sunlight and heat within a vertical closely monitored structure, reducing reliance on artificial energy sources while maintaining environmental control.

This approach balances controlled cultivation with cost-efficient operations, significantly lowering operational expenses without sacrificing quality. In other words: The hybrid model enables us to have the best of both worlds. Currently being tested in South Africa, this concept holds significant potential for Europe as well, particularly in southern regions.

Ultimately, our hybrid model offers a viable solution that strikes a balance between cost optimization and product quality. In the end, however, the decision on how much control a vertical farming project requires depends on the location of the farm and the individual goals of the operator.

Additional Efficiency Factors: The Role of Location and Resources

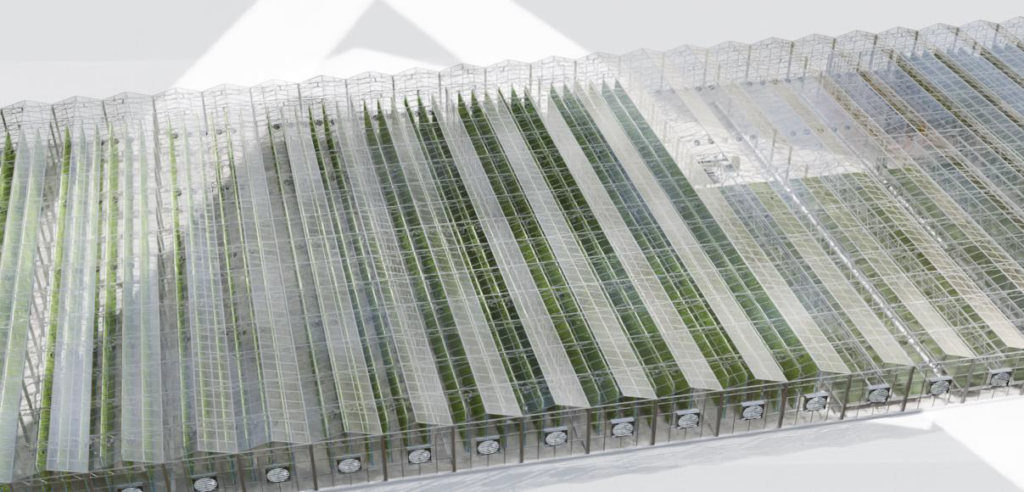

The choice of location plays a pivotal role in determining the cost-efficiency of vertical farms, as it significantly affects energy and resource usage. As mentioned, integrating renewable energy sources such as solar and wind power can substantially lower operational costs by reducing dependence on non-renewable energy sources.

Moreover, proximity to industrial facilities or other institutions offers additional opportunities for efficient resource utilization in line with circular economy principles. For example, excess heat from nearby factories can be repurposed to heat vertical farms, minimizing energy expenditures while simultaneously enhancing sustainability.

(AI-generated content, source: DALL·E)

Such synergies between site selection and resource usage not only strengthen the farm’s environmental profile but also contribute to cost reduction by lowering ongoing operational expenses.

In parallel, ongoing technological advancements will continue to play a key role in cost reduction. While some technologies remain expensive today, their affordability is expected to improve over time, making vertical farming increasingly viable. However, as operators cannot solely rely on the hope of future technological price reductions, it remains essential to pursue multiple approaches for cost optimization.

A holistic strategy combining strategic site selection, innovative resource utilization, and continuous technological improvement is therefore essential to ensure the long-term economic viability of vertical farming.

Conclusion: Strategic Compromises Between Control and Profitability

Vertical farming offers a promising solution to the challenges faced by traditional agriculture, complementing conventional food production methods with its resource efficiency and weather independence. While economic hurdles such as high investment and operational costs remain, innovative strategies like Design-to-Cost and hybrid models provide pathways to overcoming these barriers and enter a new era in food production.

Ultimately, vertical farming enterprises must strike a strategic balance between cost-efficiency, technological control, and product quality. The right approach depends on specific market conditions and geographic contexts. Flexible solutions like the greenhouse-based hybrid model demonstrate that vertical farming can be tailored to diverse conditions while remaining economically viable.

The future of vertical farming is bright, provided companies adopt innovative strategies and thoughtful models. At vGreens, we are actively addressing these challenges to shape a sustainable and economically viable future for vertical agriculture, making it a cornerstone of global food production.